We apply a modified, proprietary process flow that results in the burrs being polished down to the edge of the feature.

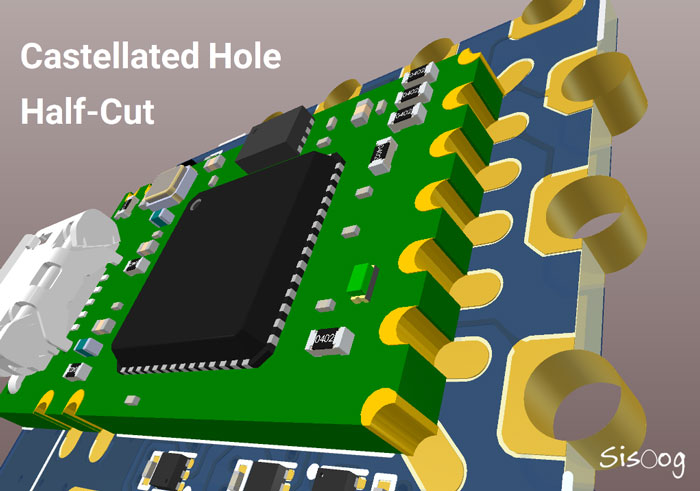

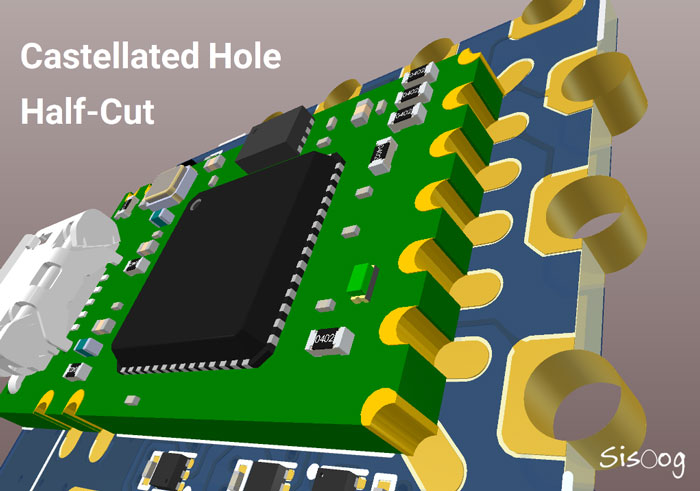

Burrs -Often edge plating, especially on castellation holes, can result in burrs from the final machining process. Next, we employ direct metallization, which has a higher copper bond strength, to prepare the surface for plating. We address this by first roughening the surface through a combination of chemical and other proprietary means. Copper Peeling -Plating over a large substrate surface can lead to the plated copper peeling due to a lack of adhesion strength. After the deposition of copper, the intended surface finish is finally applied to the edges. The outer contours, to be metallized, must be milled before through-hole plating process, as the metallization of the edges take place during this fabrication step. Drilling -> Milling Metal Slot -> Get Rid of Dirt -> Copper Electroless. Metalized Edge Plating Fabrication Process XXX plane on layer(s) N (and N) must connect to the edge plated area(s). With the addition to the note of something along the following if there is/are any plane(s) that connect to it.

Slideplating indicated area using X Oz copper.

How to define it? Make sure there is an anchor strip along the external top and bottom edges, and any plane(s) (may have) that connect to the slideplating extend out the edge and having a callout on the fab drawing that points to the relevant edge(s) that states something like: At MADPCB, we provide technical support at the front-end CAM during edge plating PCB design. Have you ever designed edge plating board? When meet a project requires slideplating PCB, some PCB designers don’t know how to define it in their Gerber files, or convey this requirement to the PCB fabricator.

0 kommentar(er)

0 kommentar(er)